Material: High purity PP material

Coating: Different specifications

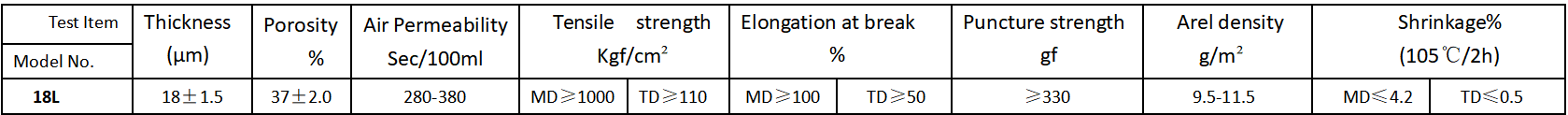

Thickness: 18±1.5μm

Width: Customization

ProductionProcess: Dry Process

Lithium-ion Battery Cell Separator/Battery Insulation Material Porous Film Battery Separator Film

Tianhong corporation has advanced international production lines for Li-ion battery separator by dry and uniaxial stretching process, equipped with high precision testing instruments, using high purity PP material and advanced production technology, mainly produce Li-ion battery separator film in thickness of 12-60 microns with different specifications, which is widely used in Li-ion power batteries, Li-ion energy storage battery and Li- ion digital product battery.

Advantages:

High safety: Multi-layer membrane efficiently reduces the safety hazards (crystal point, holes…) which are found as defects on single layer membrane; No TD shrinkage, , low MD shrinkage; Perfect heat resistance and anti-oxidant; High puncture strength & mechanical strength , suitable for high/low voltage system.

Good uniformity: Using popular dry & uniaxial stretching process, insure the pore sizes uniformity and well distributed on membrane. The separator has multi-layer structure with better thickness uniformity to improve Li-ion battery cycle life.

Excellent air permeability: High porosity, high air-permeability, low sinuosity, suitable for high rate discharging of electric vehicle Li-ion battery.

Various products: Basic separator, Ceramic coated separator, Polymer coated separator, Multi-functional hybrid coating separator, Multi-layer functional coated separator.

Certificate: