Material:

Coating:

Thickness:

Width:

ProductionProcess:

What is a ceramic?

A ceramic is an inorganic non-metallic solid made up of either metal or non-metal powders that have been blended together and hardened by heating to high temperatures. generally characteristics:

Hard and strong under compression

Chemically and thermally stable

Good electrical insulators

These properties make ceramics attractive for a wide variety of everyday and high-tech applications.

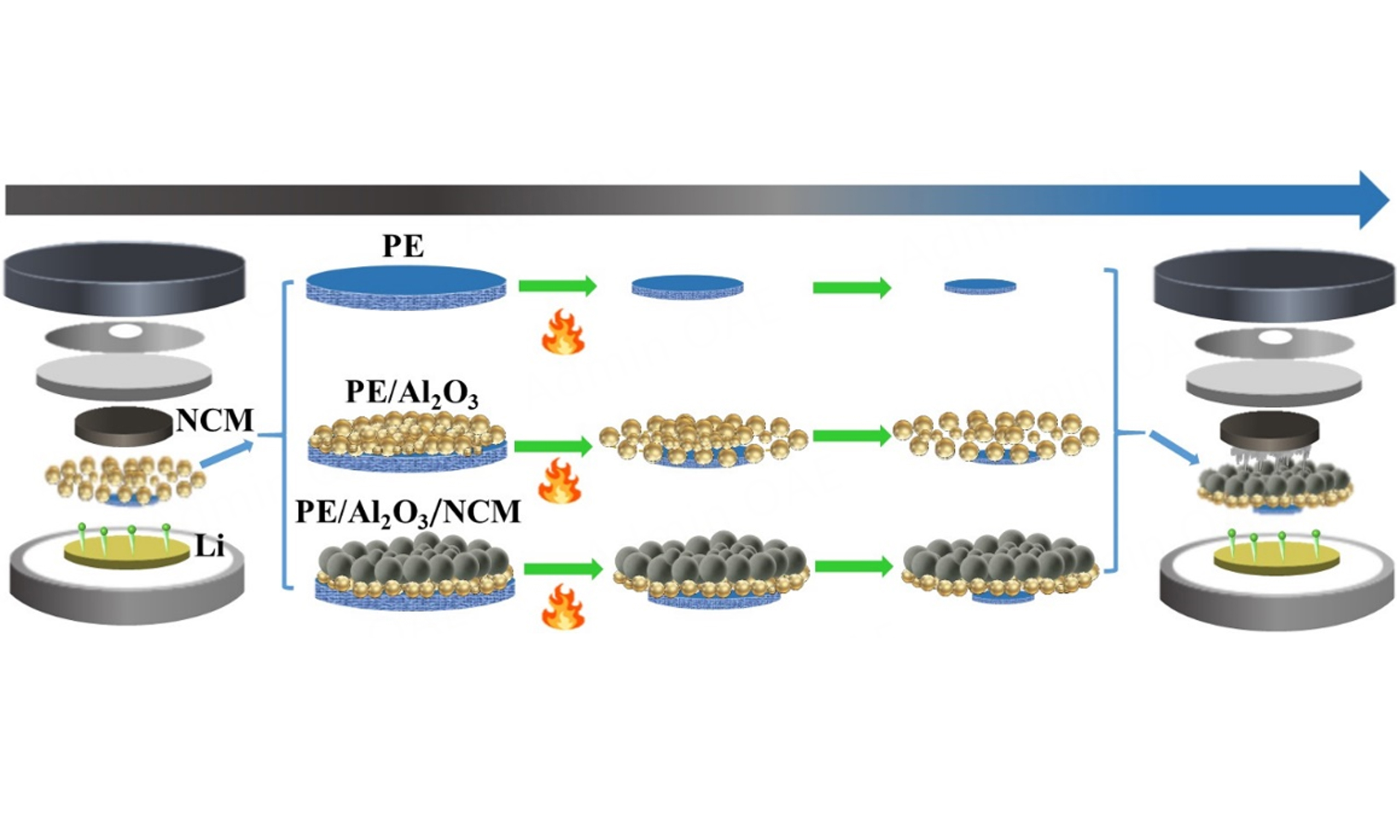

Certain properties make ceramics very attractive candidate materials for next-generation batteries. For example, the thermal stability of ceramics means far less risk of combustion or deformation at high temperatures compared to other materials, such as plastics, which soften, melt, and even catch fire under comparatively low heat. These fires are one of the main safety risks of conventional lithium-ion batteries.

Beyond thermal stability, ceramics tend to have excellent hardness, which means they resist deformation, and compressive strength, meaning they are very good at carrying loads.

Most everyday ceramics, like a plate or brick, don’t bend at all and will break if you try too hard. But when made extremely thin, ceramics can become flexible enough to bend without reaching a breaking point. This is because the amount of strain the material must withstand when bending is proportional to the distance between the bending surface and the center of the material. For a very thin ceramic, this distance is tiny, which means that the stress it experiences is quite small.

This combination of properties is the key to our battery design and scale-up strategy. On the microscopic scale, the incredible hardness of the ceramic enables it to resist lithium-metal dendrites. At the same time, the macro-scale flexibility of the separator allows it to be handled and processed in a factory setting, which is a requirement for mass production of EV batteries